Designation of a crane wheel form a with gear ring nominal diameter d1 300 mm gauge b1 50 mm bore diameter d4 80 mm h7 module 3 and number of teeth 110.

Crane wheel diameter calculation.

The formula for determining mwl is bridge weight 2 live load crane capacity hoist weight x 15 impact number of wheels on a single end truck.

Extend bearing stiffeners the full height of the girder weld to the girder top flange with full penetration welds or welds sized for the wheel loads.

74 lr 08 2010 basis of calculation for crane rail wheels din 15 070 fem 1 001 table1.

22 tonne including block tackle 1 2 x 1 2 1 44m area of outrigger pad 1 44 m 72 tonnes 1 44 x 75 x 10 converts into kilonewtons 37 500kn weight of crane weight of load area of pad.

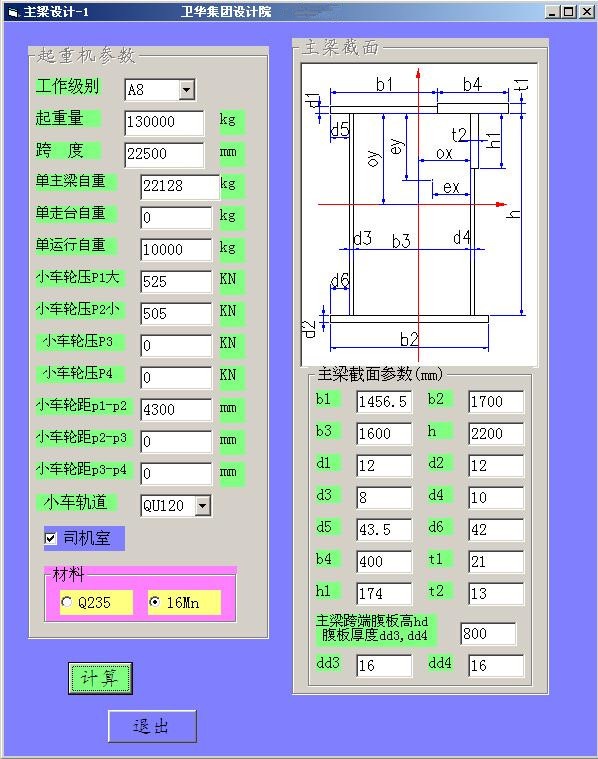

To determine the diameter of wheel checking the trolley running motor power and determine the reducer and brake model according to maximum wheel pressure.

To use the calculator please fill in the green boxes with your requirements and only the suitable cranes will be left visible below.

Wheel body 160 500 c45 drop forged.

For each tire size you input our tire calculator suggests multiple tire sizes that are with in one inch bigger and smaller of the entered tire size.

50 tonne weight of load.

Crane wheel a 300 50 80 h7 3 110 kg 010 1 form a with gear ring form b without gear ring material.

Example 2 calculate from pad size weight of crane.

Determine the size of the key components of the crane balanced.

What sets us apart is our tire suggestion guide.

This crane size calculator has been produced to allow you to estimate what you will require and to determine the logistical viability and costs associated with hiring our mobile cranes.

Symbol and unit symbol unit description explanation c1 material coefficient values in accordance with table 2 c2 speed coefficient values in accordance with table 3a and 3b c3 operating time coefficient values in accordance with table 4 d1 mm travelling wheel diameter running surface diameter.

The recommended crane size is for illustrative purposes only and may vary due to rig configuration hook height model and so on.

Wheel load design calculation of jib double girder eot crane.

3 4 column or bracket support do not use framed or clip angle type connections.

The vast majority of crane girder performance issues occur at the crane girder to column connection.

Example 3 ground bearing pressures tables.

This part of iso 16881 gives the requirements for the selection of the size for iron or steel wheels and presents the formulae for the local stresses in crane structures due to the effects of the wheel loads.

A tire size conversion calculator or tire diameter calculator is the best way to get the answers you are looking for when it comes to tire sizes.

Selection of the final crane size should be made in consultation with one of our coordinators.

Click to calculate crane size.