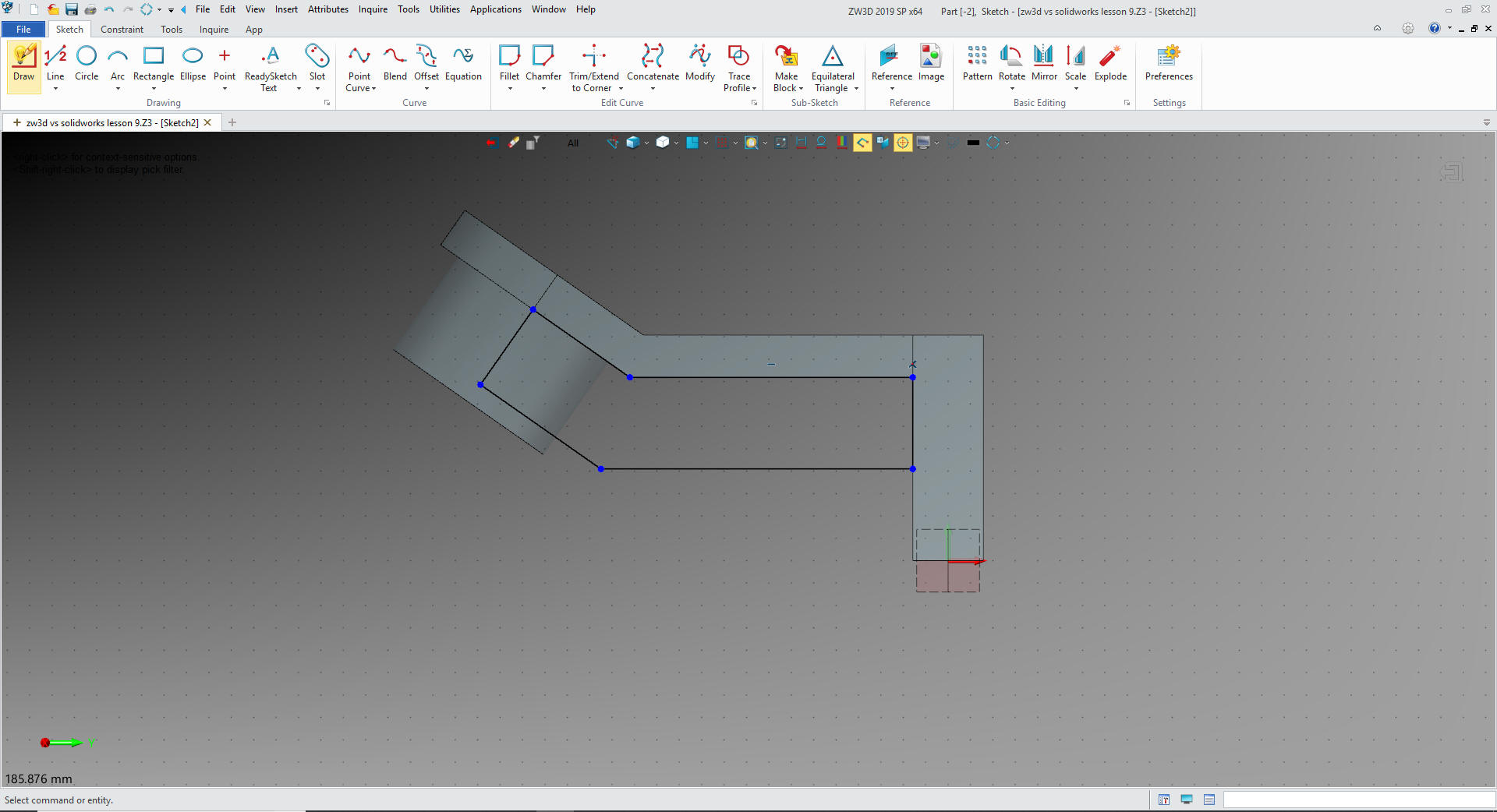

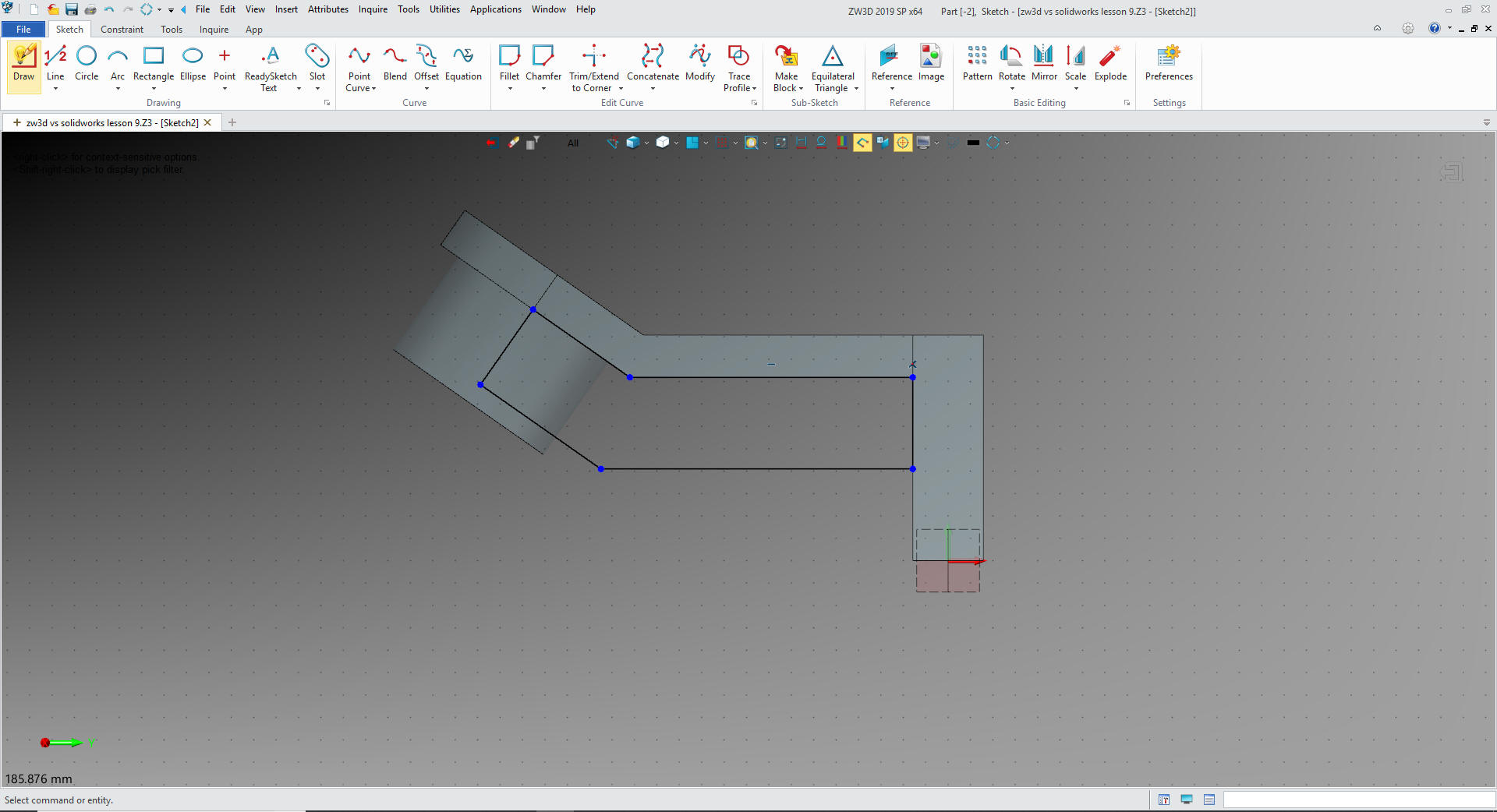

This is teh inteded corner closed with the inner edges meetign so that a fillet weld can be added to teh two faces.

Creo 2 fillet sheet metal corner.

The part has a over all dimension of 4 x 1 5.

You can see the v notch is not straight but curved edges.

The software is written on.

Hillman 12 in x 24 in copper decorative sheet metal.

What the flat pattern looks like.

No need to plug fill in a huge hole.

Should i put a fillet corner or a sharp corner.

You can see in the blue circle that the corner is not nice 4 create a new flange 3.

The part is made from sheet metal.

For pricing and availability.

Solidworks is a solid modeler and utilizes a parametric feature based approach which was initially develop by ptc creo pro engineer to create models and assemblies.

Ptc universitythingworx developer portalptc marketplace.

In this tutorial we will learn about the basic techniques related to sheet metal functionality of creo parametric by modelling a cover.

The part was originally a solid model shown.

For pricing and availability.

5 create a new flange 4 see that the bend is not nice the green circle how can i make the two red corners together.

Hillman 24 in x 36 in steel solid sheet metal.

Sheet metal parts may have sharp corners but designing a fillet of the material s thickness will make parts more cost effective.

I did this years ago in wildfire and sheetmetal did not know how to flatten it but it was good enough.

I am not 100 sure on the method that would be used to make that feature.

My question pertains to a inside corner of the part.

2 create a flange 1 manipulated in the sketch option so i have two bends 3 create a new flange 2 with a chain.

Hillman 12 in x 24 in cold rolled steel expanded sheet metal.